CNC Glass straight-line edging machine

CNC-E9 General description

CNC-E9 is suitable for processing straight-line edge & 45°arises of glass sheet with various size and thickness.

The main base is made of cast iron.

The glass thicknesses is adjusted by a servomotor and showed on a digital display.

A special design of the in-feed section for controlling the desired amount of glass removal without adjusting each spindle individually.

Independent felt wheel and the cerium water recirculation system make the flat edge more shining.

Input and output conveyor adopt timing belt which can improve the transmission precision.

It is easy to operate and has good performance.

CNC-E9 Model Explanation

9 Spindles totally: 5 spindles for the straight-line edge (adopt the independent wool felt wheel), 2 pieces of spindle for front and back arris each.

CNC-E9 Operation Condition

Power supply :AC380V±10% 3φ 50HZ±2%

Environment :Temperature : 1~40℃

R.H: 90%

CNC-E9 Technical Data

A. Processing glass thickness: 3-25mm

B. Angle of arris: 45°

C. Min.size of glass: 80mm×80mm

D. Processing speed: 0.5~4.5m/min

E. Installed power :19.08KW;

F. Dimension : 7000×1400×2500mm

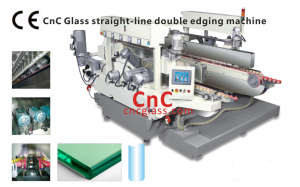

CNC Glass straight-line double edging machine

CNC2E8 is available in processing glass with thickness 3-12mm, which is produced in 8spindles (4 peripheral wheels per side) rough, fine grinding; polishing can be finished at a time. Adopt PLC for controlling. The CNC2E8 are also suitable for small production batches.

Mainly parameter:

Dimension of the whole machine (L*W*H) (mm):3270*3240*1900

Working table height (mm): 850

The Min. area of processing glass (mm2): 150*150

Processing glass width (mm): 150~1500

Processing glass thickness (mm): 3~19

Processing glass Diagonal error (mm):2m*2m≤1

Processing glass parallelism error (mm) ≤0.5/2m

The speed of transmission of processing glass (M/Min): 0.5-4.5M/Min.

(According to the thickness of glass to adjust)

Power (KW): 21.7

Voltage (V): 380

Frequency (Hz): 50

Air pressure (MPA):0.4-0.8

Weight (Kg):3500